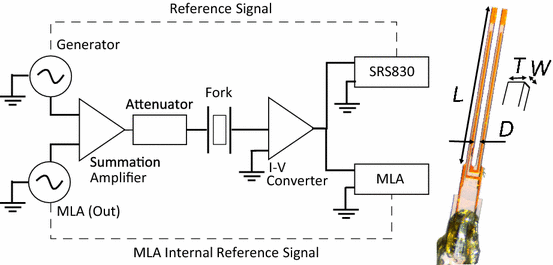

In a stark contrast with conventional QTF probes in attachment of electrochemically etched metallic wires or microfabricated AFM cantilevers, photocuring of liquid phase prepolymer within a tip mold demonstrated herein allows adhesive-free and exclusive attachment of the imaging tip onto a QTF. Exclusively for the PEGDA tip attached QTF, we demonstrate that the imaging tip could be regenerated multiple times to address issues associated with tip wear. Then, the PEGDA tip attached QTF is employed for shear force microscopy for calibration grating and atomic layers of hexagonal silicon carbide and also compared with a silicon tip attached QTF. By approaching a QTF to the negative h-PDMS tip mold filled with polyethylene glycol-diacrylate (PEGDA), a PEGDA tip is attached to the QTF without using an adhesive.

The tungsten tip of 10–100 nm radius obtained by time-controlled electrochemical etching is replicated with h-polydimethylsiloxane (h-PDMS) to make negative conical tip molds large enough to be used for QTFs. It is proved that it is possible to construct a miniature quartz tuning-fork temperature sensor with high sensitivity and small non-linearity.This paper reports the first demonstration of hydrogel conical tip attachment onto quartz tuning fork (QTF) by using an elastomeric tip mold that is soft-lithographically replicated from an electrochemically etched tungsten wire. The temperature sensor based on quartz tuning-fork thermo-sensitive resonator is mounted in a standard holder for use from −30 degree C to 160 degree C with an accuracy of 0.05 degree C and a high resolution of 0.001 degree C.

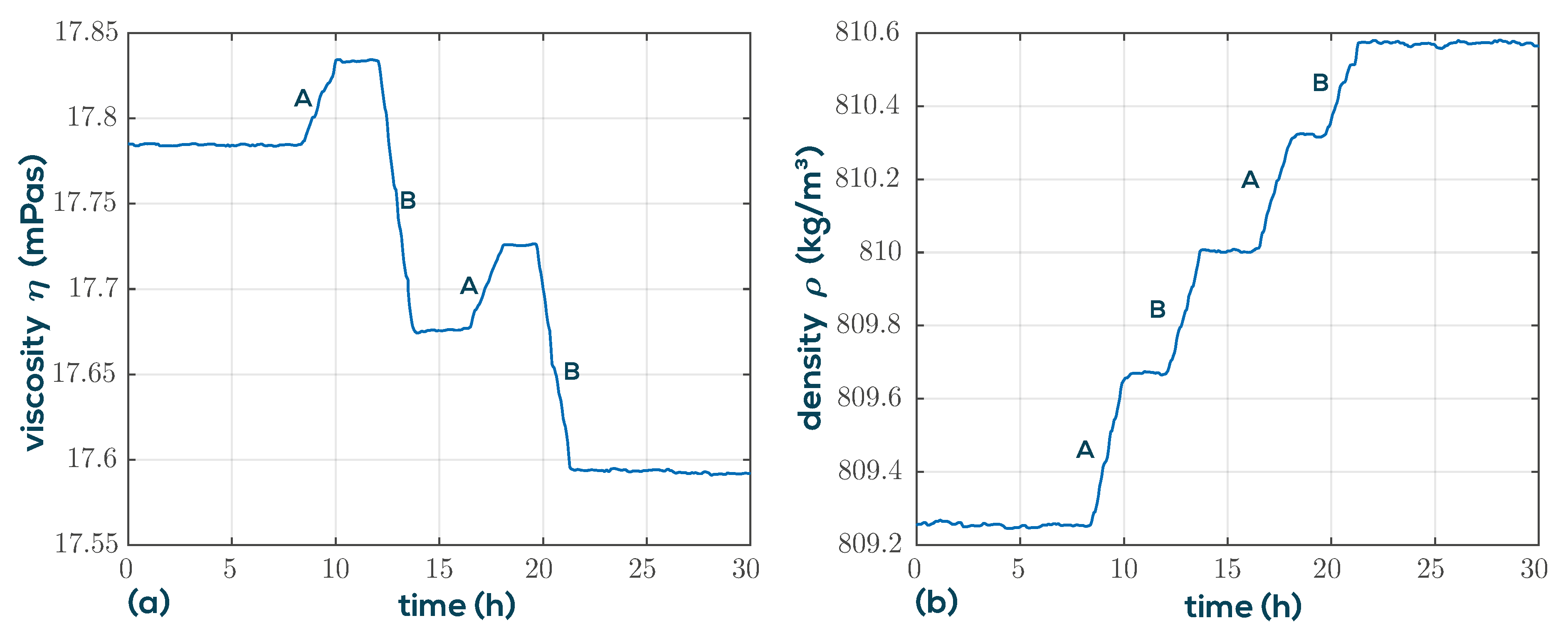

Using ZYtw-cut can bring the temperature coefficient up to 70ppm/(degree C) and make power consumption lower. The results obtained from the experimental investigations show the method which synthesizes many factors to design quartz tuning-fork temperature sensor. Precise temperature versus frequency analyses of resonators have been carried out and Least Mean Squared (LMS) curve fit algorithm is applied to compute the temperature values quantitatively. This type of sensor designed with a new ZYtw-cut is proved that working at flexural vibration mode was better than at the others modes.

#Quartz tuning fork sensor series

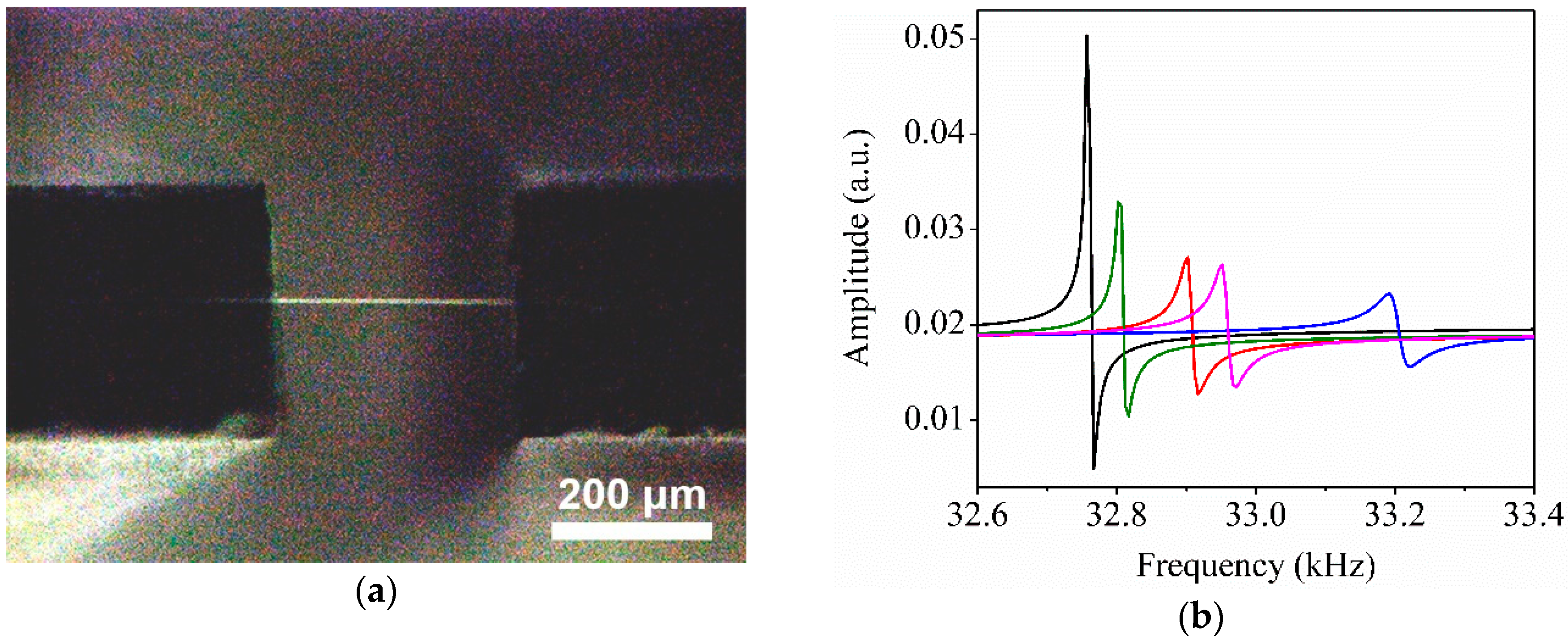

In order to optimize the design of quartz tuning fork temperature sensor, finite element method (FEM) is applied to model optimum tuning fork geometry, tine tip and tine surface electrode shape and thickness with a resonance frequency close to 32 kHz and a series resistance value of 40 kΩ as design targets.

0 kommentar(er)

0 kommentar(er)